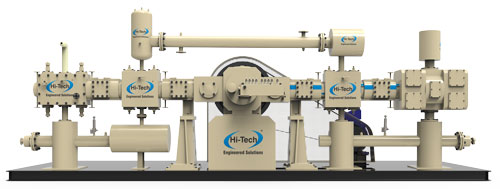

Hi-Tech Cryogenic Oxygen/Nitrogen Plants is designed and built to the highest standards of reliability and efficiency to meet the most severe operating conditions. Each plant is assembled completely, thoroughly inspected and tested for performance under actual operating conditions to assure the highest level of quality. The modular design of the HTO Series plant minimizes transportation and handling expense and enables rapid on-site installation. Packaged for shipment in two 40’ ISO containers, the plant can normally be installed and commissioned within two days, requiring only a simple foundation. On-site plants make the constant supply of nitrogen or oxygen less reliant on delivered liquid. Proven cryogenic technology combined with a robust control system makes our plants a source of reliable gas supply.

Why Hi-Tech Gas Plants

Efficient, reliable oil-flooded compressor

High-performance oil free Air Expander

Cost Saving of up-to 50% from Cryogenic liquid supply

Proven air pre-purification clean up system

Choice of 50 or 60 Hz power systems

Choice of 220 to 440 V Electrical power systems

Ships as standard ISO containers to minimize transportation expense

Complete with all interconnecting piping & electrical systems, ready for installation

Dependable Highest Reliability with Energy Efficiency

Compact design with Easy and Simple controls

State-of-the-art analytical instrumentation package

Easy to maintain with continuously monitored Purity & Flow

Integrated cylinder filling system for oxygen & nitrogen

Optional product storage tank

Optional Fully Automatic touch screen control

Completely Pre-Piped & Skid Mounted.

Full containerized shipments right from factory.

All Steel design suitable for Medical grade oxygen as per US or EN Pharmacopeia.

Automatic shutdown for in case of high Temperature, High Pressure

Designed in accordance with local standards.

On-site start-up Training and assistance by Hi-Tech’s technicians anywhere in the World.

Cyclone Air Filter

Air Compressor

Process Skid

Specially selected adsorbent materials

Cold Box Assembly

Air Expander

Liquid Oxygen Compression

Oxygen & Nitrogen Cylinder filling ramp

Oxygen & Nitrogen Product Analyzer

Electrical Panel

Electric Induction Motors

Interconnecting pipelines

Set of insulation materials

Set of installation spare-parts

Our Plant Provides from 30 to 500 Nm3/hr of Oxygen Gas. Use the following Table to determine which model is most suitable to your application.

| Model

Parameter |

HTO-30 | HTO-50 | HTO-80 | HTO-100 | HTO-150 | HTO-200 | HTO-300 | HTO-500 |

| Production | ||||||||

| Gas Oxygen Nm3/hr | 30 | 50 | 80 | 100 | 150 | 200 | 300 | 500 |

| Gas Nitrogen Nm3/hr | 8 | 18 | 29 | 40 | 65 | 85 | 135 | 235 |

| Purity | ||||||||

| Oxygen %O2, min | 99.6 | 99.6 | 99.6 | 99.6 | 99.6 | 99.6 | 99.6 | 99.6 |

| Nitrogen ppm O2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Product Pressure | ||||||||

| Oxygen Bar max | 220 | 220 | 220 | 220 | 220 | 220 | 220 | 220 |

| Nitrogen Bar max | 415 | 415 | 415 | 415 | 415 | 415 | 415 | 415 |

| Utilities | ||||||||

| Power KW | 55 | 85 | 125 | 150 | 225 | 290 | 425 | 700 |

| Specific Power KWhr/Nm3 | 1.25 | 1.2 | 1.1 | 1.0 | 1.0 | 0.85 | 0.8 | 0.75 |

| Cooling Water

Makeup lpm Temperature Deg C |

4

25 |

8

25 |

12

25 |

14

25 |

18

25 |

18

25 |

20

25 |

20

25 |

-Plant performance is based on standard atmospheric conditions (ambient temperature 20° C, relative humidity 50%, cooling water temperature 19ºC, 1.0 atm. barometric pressure)

-Higher Capacity / Custom Built units also available, makeup with recirculated cooling water system, Specific power excludes cooling water system.

Installation and commissioning assistance

Extended warranty package

AMC / Service package

COLD BOX WITH AIR EXPANDER